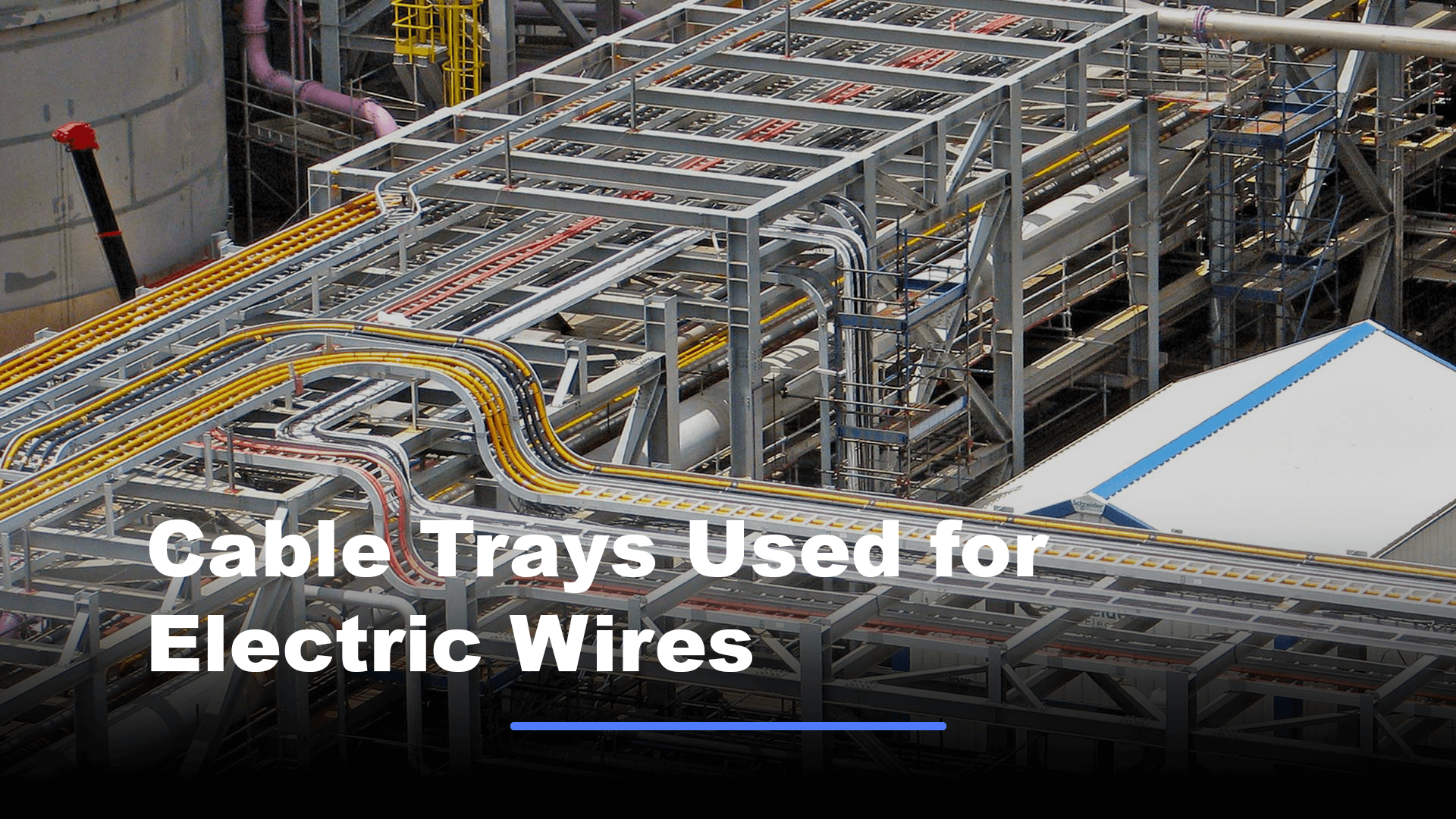

17 Dec Cable Trays Used for Electric Wires

Cable trays are a solid structural system made consisting of a single unit or a group of them along with the necessary fasteners to support, route, and secure the cables.

As an alternative to open cabling or conduct systems, cable tray systems are used to support cables for power distribution, control, and communication in cable management in commercial and industrial applications.

Where frequent changes in installations are anticipated, the Cable Tray Systems are highly helpful. By replacing/laying new cables in the current cable tray systems, cabling networks can be upgraded, expanded, rerouted, or relocated without causing significant disruption or deviance. The Cable Tray facilitates the ideal routing path for both above and underground wires in addition to provide mechanical support.

In order to hang and support insulated power, control, and communication wires, cable tray systems serve as a bridging device.

The cable tray systems are typically open in design, allowing for effective heat dissipation and simple inspection access.

Advantages of Cable Tray Systems

Money saving: Cable tray prices in India are cheap and a great source to use to protect your wire in the production floor.

Maintenance: Cable trays maintenance is done because wires/cables keep entering and exiting the trays every time so by maintaining the cable tray it will be easy to remove the wires when needed.

Safe: Cable trays are mostly installed at places which are hard to reach places.

Different Types of Cables

Solid bottom type

Perforated type

Ladder type

Wire mesh

Channel type

Solid bottom trays offer the highest level of protection, but there are no ventilation options available for heat dissipation. Cutting of trays and other fittings are also necessary for cable entry and escape during installation.

The Perforated Cable Trays enable for air flow, water drainage, and dust fall thanks to openings in the bottom of the trays. For minor cable entry and exit, the ventilation opening’s slots and holes can be used.

The Ladder Trays are equipped with multiple bars that resemble ladder rungs spaced regularly apart by 100mm to 300mm for supporting the cables.

Ladder and Perforation trays are used To protect cabling from falling items, dust, etc.,they also have solid coverings. The tray covers intended for outdoor use may have a sloppy form to shed particles such as snow, ice, or dust.

The lighter cable trays are used in situations where there are plenty of little cables, like telephone or computer network cables. Wire mesh, commonly known as cable baskets, can be used to create these cable trays.

When conduit is not desired, the cable departure is provided through a ventilation aperture and channel trays are utilized for installations with a small number of cables. The channel trays may also absorb some vibrations, and some vibrations must be absorbed. The channel trays are also used to branch off of the main cable tray systems and dump cables.

The Materials Used

Powder-coated sheet, galvanized steel, stainless steel, aluminum, or fiber-reinforced plastic are the most popular materials used to make cable trays.

Depending on the use and environment, a given use’s cable trays are made of a certain material. The galvanized steel trays can be made from pre-galvanized sheet or after being hot-dipped galvanized.

Trays made of stainless steel, fiberglass, and fiber glass reinforced plastic are utilized in environments where a beautiful appearance is desired yet a corrosive environment prevails.

For rust resistance and longer life, Cable Trays are often painted or powder coated. Additionally, it looks fantastic after installation. In chemical environments, aluminum cable trays with exceptional corrosion resistance are used in paper mills and petrochemical plants, among other places.

Product lines designed for installations with special requirements are available In one of the Top leading cable tray manufacturers in india like Hutaib Electrical . For instance, if a cable tray needs to be run over a road as part of an installation, it must be sturdy enough to span 30 feet between supports. The short span, with supports every 4 to 5 feet, is at the other extreme of the product spectrum and may need to be field-adaptable to match the constrained space requirements of a retrofit. A wide range of factors may also exist between these sets of criteria, which can be addressed by various cable tray devices. In actuality, larger and larger cable trays that allow for future cable expansion are needed.For installations done today, manufactured support systems that can accommodate Category 5 and 6 cables are required. Manufacturers of cable trays in India are keen to offer future performance warranties as the performance of the products continues improving daily. In order to prevent poor cable tray management from affecting the performance of the cable tray, it is therefore necessary to have one of the best cable trays.

No Comments